The Benefits & Uses of Welded Wire Mesh in Industrial and Construction Applications

Welded wire mesh is a versatile and durable material that has numerous benefits and uses in industrial and construction applications. Its strength, customizability, cost-effectiveness, and versatility make it an ideal choice for creating bespoke solutions that meet the specific needs of each industry and scenario. Welded wire mesh is widely used in construction for reinforcing concrete structures, creating fencing and barriers, and creating storage solutions in the manufacturing industry. It is also used in agriculture, transportation, security, landscaping, and filtration industries. The material's impressive range of benefits includes strength and durability, customizability, cost-effectiveness, speed of installation, and versatility. By choosing welded wire mesh for industrial and construction applications, you can ensure that your project is efficient, effective, and meets the required standards.

What is Welded Wire Mesh and Why is it Used in Multiple Industries

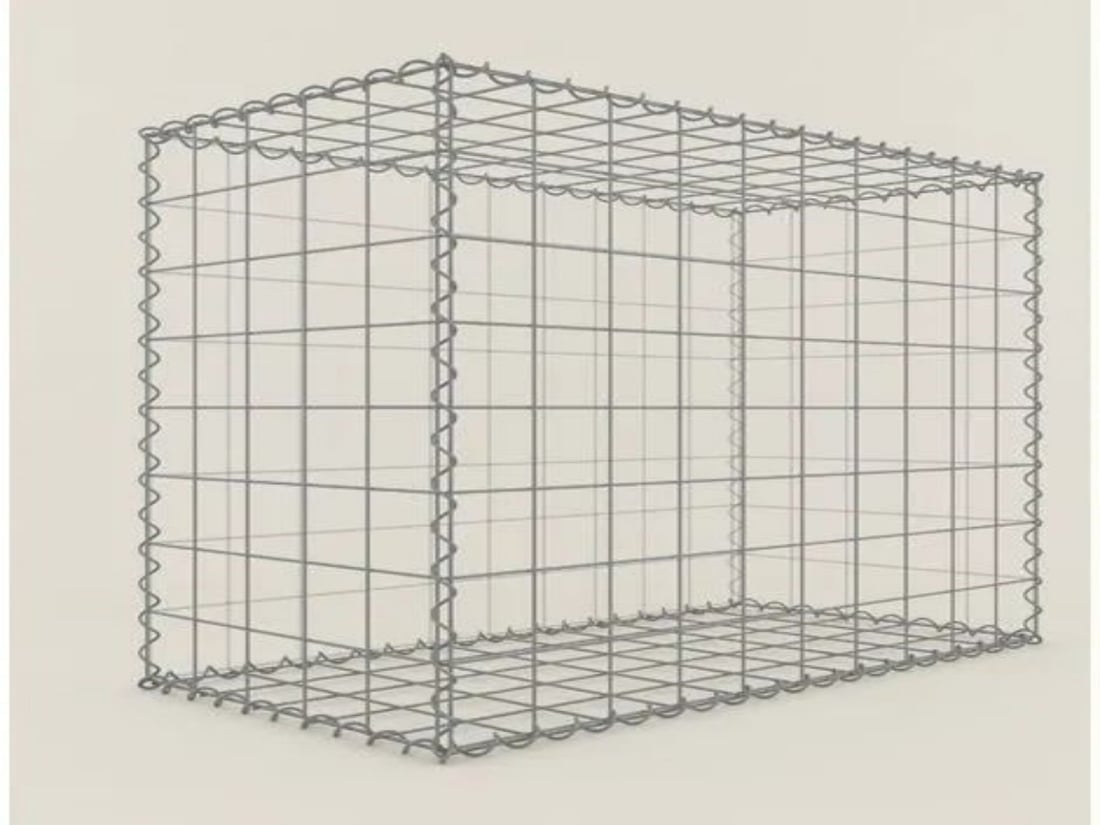

Welded wire mesh is a type of wire mesh that is made by welding individual wires at their intersections. This results in a mesh that is strong, durable, and highly resistant to deformation. Welded wire mesh is used in multiple industries due to its versatility and strength. Its strength, durability, and resistance to deformation make it a popular choice for many industries. The ability to customize the mesh to specific needs and sizes makes it a preferred choice for applications that require strong and reliable material. With its many uses and benefits, welded wire mesh is an important material for modern construction and manufacturing processes.

Types of Wire Mesh for Different Uses – Choose the Right Type for Your Application

Wire mesh is a versatile material that is used in a wide range of applications across various industries. It is made by weaving or welding wires together to create a mesh structure. The type of wire mesh used can vary depending on the intended use and the specific requirements of the application. In this part, we will explore the different types of wire mesh and their uses.

Welded Wire Mesh: Welded wire mesh is made by welding individual wires at their intersections. This results in a mesh that is strong, durable, and highly resistant to deformation. Welded wire mesh is commonly used for reinforcing concrete structures such as walls, floors, and foundations, as well as for creating fencing and barriers. It is also used in the manufacturing industry for creating storage cages, racks, and shelving.

Woven Wire Mesh: Woven wire mesh is made by weaving wires together to create a mesh structure. This results in a mesh that is flexible and can be easily customized to fit specific needs. Woven wire mesh is commonly used in filtration, sieving, and screening applications. It is also used for creating partitions, protective barriers, and for insect and bird control.

Expanded Metal Mesh: Expanded metal mesh is made by cutting and stretching a sheet of metal to create a mesh structure. This results in a mesh that is strong, durable, and lightweight. Expanded metal mesh is commonly used in fencing, grating, and walkway applications. It is also used for creating decorative panels and building facades.

Perforated Metal Mesh: Perforated metal mesh is made by punching holes in a sheet of metal to create a mesh structure. This results in a mesh that is strong, durable, and lightweight. Perforated metal mesh is commonly used in filtration, ventilation, and acoustic applications. It is also used for creating decorative panels, screens, and building facades.

Knitted Wire Mesh: Knitted wire mesh is made by knitting wires together to create a mesh structure. This results in a mesh that is flexible, compressible, and can be easily customized to fit specific needs. Knitted wire mesh is commonly used in filtration, vibration damping, and noise reduction applications. It is also used for creating seals, gaskets, and wire cloth.

Hexagonal Wire Mesh: Hexagonal wire mesh is made by weaving wires together in a hexagonal pattern to create a mesh structure. This results in a mesh that is strong, durable, and lightweight. Hexagonal wire mesh is commonly used for creating poultry and livestock enclosures, as well as for erosion control and slope stabilization. It is also used for creating decorative garden fences and plant supports.

All in all, there are different types of wire mesh that are suitable for different applications. The choice of wire mesh will depend on the specific requirements of the application, including strength, durability, flexibility, and customization. By choosing the right type of wire mesh, you can ensure that your application is efficient, effective, and meets the required standards.

Impressive Benefits of Using Welded Wire Mesh for Construction Work

Welded wire mesh is a popular material for use in construction work due to its impressive range of benefits. Made by welding individual wires together, welded wire mesh is a highly versatile and durable material that has numerous applications in the construction industry. In this section, we will explore the impressive benefits of using welded wire mesh for construction work.

Strength and Durability: Welded wire mesh is highly resistant to deformation and is able to withstand high levels of pressure and stress. This makes it an ideal material for reinforcing concrete structures such as walls, floors, and foundations, as well as for creating fencing and barriers.

Customizability: Welded wire mesh is highly customizable, and can be easily modified to suit specific needs and requirements. This makes it an ideal material for creating storage cages, racks, and shelving in the manufacturing industry.

Cost-effectiveness: Welded wire mesh is a highly cost-effective material, making it an ideal choice for construction projects that require a strong and durable material at an affordable price. This is particularly important for large-scale construction projects where cost savings can make a significant impact on the overall budget.

Speed of installation: Welded wire mesh is relatively quick and easy to install, making it a popular choice for construction projects where time is of the essence. The mesh can be easily cut and shaped to fit specific requirements, and can be quickly secured in place using appropriate fasteners.

Versatility: Welded wire mesh is a highly versatile material that can be used for a wide range of applications in the construction industry. This includes reinforcing concrete structures, creating fencing and barriers, and creating storage solutions in the manufacturing industry.

In general, the impressive benefits of using welded wire mesh make it an ideal material for construction work. Its strength, durability, customizability, cost-effectiveness, speed of installation, and versatility make it a popular choice for a wide range of applications in the construction industry. By choosing welded wire mesh for your construction project, you can ensure that your project is efficient, effective, and meets the required standards.

Applications of Welded Wire Mesh in Various Industries & Scenarios

Welded wire mesh is used in multiple industries due to its versatility and strength. In this section, we will explore the applications of welded wire mesh in various industries and scenarios.

Construction Industry: One of the most common applications of welded wire mesh is in the construction industry. It is used for reinforcing concrete structures such as walls, floors, and foundations, as well as for creating fencing and barriers. Welded wire mesh is also used in the manufacturing industry for creating storage cages, racks, and shelving.

Agriculture Industry: Welded wire mesh is widely used in the agriculture industry for creating animal enclosures, poultry cages, and rabbit hutches. The material is durable and highly resistant to deformation, making it ideal for use in outdoor environments.

Transportation Industry: Welded wire mesh is also used in the transportation industry for creating cargo and storage containers. The material is highly customizable and can be easily modified to fit specific requirements, making it an ideal choice for creating containers that meet the specific needs of the transportation industry.

Security Industry: Welded wire mesh is commonly used in the security industry for creating barriers and enclosures. It can be used for securing commercial and industrial premises, as well as for creating secure storage solutions.

Landscaping Industry: Welded wire mesh is used in the landscaping industry for creating decorative garden fences, plant supports, and trellises. The material is highly customizable and can be easily modified to fit specific requirements, making it an ideal choice for creating bespoke landscaping solutions.

Filtration Industry: Welded wire mesh is also used in the filtration industry for creating filter screens, sieves, and strainers. The material can be easily modified to meet specific filtration requirements, making it an ideal choice for creating custom filtration solutions.

Related Blog: The Complete Guide to BARBED WIRE and How It Is Used in Different Fields

Overall, welded wire mesh is a versatile material used in a wide range of applications. the applications of welded wire mesh are diverse and wide-ranging, making it a highly versatile material that is used in many different industries and scenarios. Its durability, customizability, and versatility make it an ideal choice for creating bespoke solutions that meet the specific needs of each industry and scenario. With its many uses and benefits, welded wire mesh is an important material for modern construction and manufacturing processes.

For more information, please contact us directly, our staff will reply to you as soon as possible. You can contact us by the following ways:

Email: [email protected]

Tel/WhatsApp/Wechat: +86-19905898030.