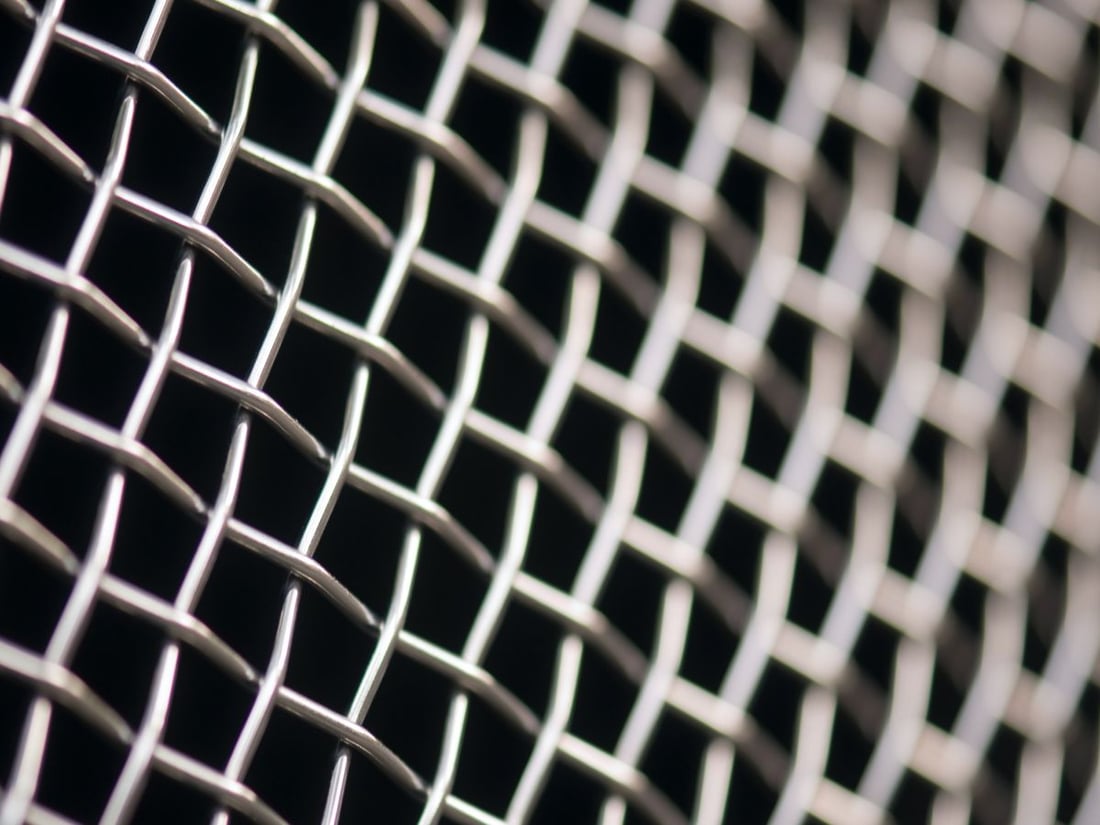

Understanding the Durability of Coated Wire Mesh

Coated wire mesh offers enhanced durability, making it suitable for various applications where strength and longevity are essential. Let's delve into the factors that contribute to its durability:

Corrosion Resistance: Coated wire mesh is specifically designed to resist corrosion. The coating acts as a protective layer that shields the underlying metal from exposure to moisture, chemicals, and environmental elements, extending the lifespan of the mesh.

Impact and Abrasion Resistance: The coating on the wire mesh provides additional protection against impact and abrasion. This makes it highly durable and capable of withstanding harsh conditions and heavy usage.

UV Resistance: Coated wire mesh with UV-resistant coatings offers protection against the damaging effects of sunlight. It retains its strength and appearance over time, making it suitable for outdoor applications exposed to direct sunlight.

Exploring the Versatility of Coated Wire Mesh

Coated wire mesh is a versatile material that finds applications in various industries. Its flexibility and adaptability contribute to its widespread use. Let's examine some key areas where it excels:

Filtration and Separation: Coated wire mesh is widely employed in filtration and separation processes across industries. Its precise mesh openings and customized coatings allow for efficient particle retention and separation, making it invaluable in chemical, pharmaceutical, and food processing industries.

Safety and Security: Coated wire mesh serves as a reliable safety and security solution. It is used in safety barriers, fencing systems, and enclosures, providing protection while allowing visibility and airflow. The coating enhances the mesh's durability and resistance to tampering.

Architectural and Decorative Applications: Coated wire mesh adds aesthetic appeal to architectural projects and interior design applications. With a range of customizable coatings, it can be used as decorative panels, room dividers, and façade cladding, providing a modern and visually appealing finish.

Customization Options for Coated Wire Mesh

Coated wire mesh offers customization options to suit specific project requirements and design preferences. Consider the following aspects that can be customized:

Coating Type and Color: Coated wire mesh can be customized with various types of coatings, such as PVC, polyester, epoxy, or nylon, depending on the desired properties and environment. Additionally, a wide range of color options allows for seamless integration into design schemes.

Mesh Size and Wire Diameter: Coated wire mesh can be tailored to different mesh sizes and wire diameters, offering flexibility in terms of filtration precision, strength, and desired visual effects.

Surface Texture: The coated surface of wire mesh can be customized to achieve specific textures, such as matte, glossy, or textured finishes. These textures enhance the aesthetic appeal and tactile qualities of the mesh.

In conclusion, coated wire mesh offers enhanced durability, corrosion resistance, and versatility. Its applications range from filtration and safety to architectural design and decorative purposes. Invest in high-quality coated wire mesh to optimize functionality and aesthetics in your projects.